POLYCARBONATE LAMINATED GLASS

This is a safe laminated glass with strong impact resistance.

- HOME

- Introduction of technology

- LAMINATED GLASS

- POLYCARBONATE LAMINATED GLASS

POLYCARBONATE LAMINATED GLASS

This is a safe laminated glass with strong impact resistance.

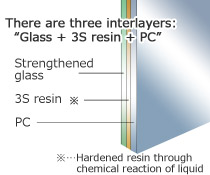

The interlayer can be finished even if coefficients of linear expansion of

PC and glass have great difference.

It can be formed into any special shape! If necessary, please contact with us at any time!

Industrial mechanical safety glass

Japanese industry machinery manufacturers have laid a solid foundation for their whole industry with their unique technologies, and have made great contribution to Japanese industry development. Nowadays, the manufacturers are making unremitting efforts to improve industrial machinery highly-sophisticated technologies. The R&D competition is increasingly sharp.

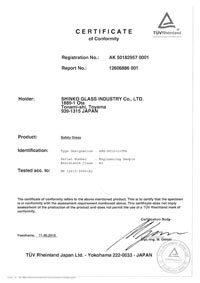

In this background, we as a manufacturer dedicated to glass finishing have obtained TUV(*) product certification and launched safety glass with unique technologies.

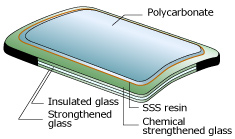

The impact resistance can be improved by using PC. The observation windows of heavy-duty vehicles, Shinkansen Line vehicles and processing machinery are easy to deform in case of thermal expansion, so size of the glass is limited. Our products are used for these products, and are accepted after verification using JIS R 3213 Railway Vehicle Safety Test Method.

- Impact-proof windows of processing machinery

-

The windows play an important role in protection of precious materials and tools, and need high impact resistance. Combing glass with PC can meet the requirement. The glass has hard surface, and can prevent corrosion of chemical reagents and oil. In the environment with cutting powder and cutting oil, the slight line is smooth.

Besides, PC has high impact resistance and can prevent accident of impact during finishing. Also, the middle resin layer can reduce noise.

- Windshield of heavy-duty vehicles

-

As a safety glass, it can achieve high impact resistance by combing PC with glass, and passed the falling ball impact test in the JIS R 3212 (Vehicle Safety Glass Test Method). It is used for side widows of high-speed railway vehicles.

- Safety windows of building machinery

The operation room’s skylight of the building machinery needs a clear vision and protect it from impact of dangerous goods. We hope our products can be widely applied to this field.

Processing machinery

Processing machinery Vehicles

Vehicles Building machinery

Building machinery

Features of Shinko polycarbonate laminated glass

- The safety can be enhanced by changing thickness of glass and PC. The interlayer is not heated. It is finished at normal temperature and normal pressure.

- In this way, residual stress and thermal deterioration of PC caused by heating and different coefficient of thermal expansion of other materials can be prevented.

*...TUV is a third party certifying body with high recognition degree in product safety evaluation of European market. We have obtained EN-12415 certificate for our glass and PC laminated glass.

Consulting & Application of company information

Shinko laminated glass

- Resin laminated glass

- Film laminated glass

- Polycarbonate laminated glass